Features

Structures & Equipment

Water and irrigation

Water Treatment: What System Should I Choose?

Choosing a water treatment technology can be a complex decision. Consider the options, initial and ongoing costs, as well as your operation’s specifics.

March 21, 2022 By Dr. Chevonne Dayboll

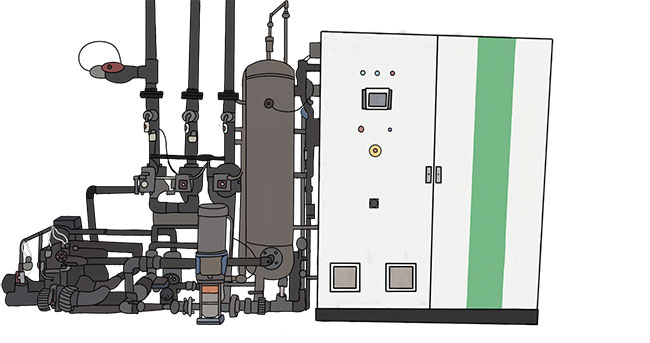

Ozone treatments can remove pathogens and break down organic chemicals such as pesticides or plant growth regulators. All images courtesy of OMAFRA

Ozone treatments can remove pathogens and break down organic chemicals such as pesticides or plant growth regulators. All images courtesy of OMAFRA If you don’t currently treat your water it may be time to seriously consider a treatment system.

There are a number of steps to take that can help reduce losses from fungal and bacterial diseases. These include sourcing pathogen-free cuttings, making sure your water source and water-holding tanks are problem-free, as well as practising good sanitation in your greenhouse. Chief among them is another important step – the use of water treatments to reduce pathogen loads.

Looking into water treatment technologies can be overwhelming. There are many options out there and you need to consider your operation’s specifics. Add in the initial and ongoing costs, and the decision can become a complex one.

A few years ago, our friends at Flowers Canada Ontario (FCO) and the Soil Resource Group (SRG) came up with a guidance document to assist growers in choosing water treatment systems. It covers why you might want to treat your water and which systems are best for common problems like sediment, fungi, viral or bacterial issues. It also addresses costs, installation, space requirements and maintenance considerations.

In this article, we have identified factors to consider before moving forward with an installation as well as information about four commonly chosen water treatment options for consideration.

Treatment Options

Considering the parameters of your farm, you might need a fairly simple solution or something more complex. Here are four commonly chosen options for greenhouse use and some considerations to keep in mind. It’s important to note that they are not the only solutions available. Some farms may also benefit from several different ways to treat their water in series because of their crops, setup or disease pressure.

Ultraviolet Light (UV)

How it works: Damages DNA of pathogens and prevents reproduction by exposing them to UV radiation.

Type: Physical

Capital Cost: High

Operational Cost: Low

Footprint: Small

Considerations:

- Requires clear and colourless water to work optimally, so water with high turbidity, sediment or colour will need a pre-treatment (like filters or a constructed wetland)

- Good choice for pathogen removal, especially in sensitive crops

- Good choice for growers managing high volumes of irrigation water

- Allows retention of nutrients if recirculating water

- Costly, especially if the volume of water warrants several units.

Ozone

How it works: Splits ozone particles into oxygen and a free radical which destroys pathogen cell membranes.

Type: Chemical

Capital Cost: High

Operational Cost: Moderate

Footprint: Moderate

Considerations:

- Like UV, water may need pre-treatment to reduce turbidity, sediment, etc. It can react with compounds in the water which can reduce efficiency.

- Removes fungi, bacteria and viruses, and breaks down organic chemicals such as pesticides or plant growth regulators

- Controls biofilm if used properly

- Ozone itself is very unstable and must be generated on-site.

- Can add oxygen to the water which can improve root health

- Costly, especially if the volume of water warrants several units

Electro-chemical activation (ECA) can offer good pathogen and biofilm control.

Electro-Chemical Activation (ECA)

How it works: Passing a salt solution (generally potassium chloride, KCl) through an electrical current creates chlorine gas which dissolves into the water forming compounds which are antimicrobial.

Type: Chemical

Capital Cost: Moderate

Operational Cost: Moderate

Footprint: Moderate

Considerations:

- Requires a product (KCl) to run which must be purchased to create your own treatment solution (low cost, but an ongoing one)

- Getting the right amount of active ingredient is a learning process, and it takes some optimization to get it right. Too much can result in phytotoxicity, too little doesn’t control pathogens. Regular water tests can help to see if it is working properly.

- Good pathogen control if monitored and maintained

- Controls biofilm if used properly

- May not be the best solution for chlorine-sensitive crops (buildup of ions (K and Cl) must be managed)

- Can be injected at multiple sites (e.g., at cloth filter before it goes into feedwater storage tanks, or as water goes out to crop)

- Moderately costly to install

Woodchip Bioreactors and Hybrid Treatment Systems (HTS)

How they work: The woodchip cell creates an environment with zero free oxygen, so beneficial microbes can degrade unwanted compounds (nitrate-nitrogen, and fungal pathogens). Additional compounds may also be removed, including pesticides and plant growth regulators. In an HTS, the woodchip cell is followed by mineral media cells to remove other compounds such as phosphorus. Media can be specifically tailored to meet the growing operations’ requirements.

Woodchip Cell Alone:

Type: Biological

Capital Cost: Low

Operational Cost: Low

Footprint: Moderate

Hybrid Treatment System:

Type: Biological/Chemical/Physical

Capital Cost: High

Operational Cost: Low

Footprint: High

Considerations:

- Can remove nutrients and fungal pathogens from water, as well as some pesticides and PGRs

- Water quality is suitable for irrigation but can have high bicarbonates and should be blended with fresh nutrient solution if used on sensitive crops.

- Can handle seasonal water fluctuations

- Maintenance is fairly simple. Woodchips will need to be replaced as they degrade, but they have a lifespan of many years if the system is operated properly.

- HTS needs space for an in-ground system outside of the greenhouse, but can be installed under a growing area (machine traffic should be avoided).

- For more, check out the results of this experiment testing different media in HTS systems

Questions to ponder

Before getting started on an installation, there are many aspects to consider:

What is the size of your operation? Do you have any future plans for expansion?

How do your production

cycles work? Do you have heavy seasons, or fairly predictable week-to-week production?

What’s your water source? Does your irrigation water come from a well, a city or do you collect rainwater? Does the source change over the year? Do you blend water sources?

What’s the water quality, and what is the volume you need to treat? Does it have sediment, or have you had disease issues?

What types of crops do you grow? Sensitive varieties might require more vigorous treatment

What’s your budget? What costs can you handle for upfront installation and ongoing maintenance?

How much maintenance can

you handle? Is your ideal system a set-it-and-forget-it solution, or will it have downtime or need to be calibrated on a regular basis?

Acknowledgements

This article was written with input from Dr. Jeanine West of PhytoServ and

Dr. Ann Huber of Soil Resource Group.

For more information, please check out the guidance document on water treatments, contact the authors, or reach out to a water treatment specialist.

This is the fifth article in a series on water sanitation that first appeared on ONfloriculture.com. The goal of this series is to encourage greenhouse operations to reflect on their irrigation systems before they are faced with a problem.

The first article revealed where problems are likely to occur in the greenhouse; the second explored the types of pathogens found in water, the third covered where and how to sample your water and the fourth was on water DNA tests – all can be found on ONfloriculture.com.

Chevonne Dayboll, PhD, is the greenhouse floriculture specialist at the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA). Have questions? Email chevonne.dayboll@ontario.ca.

The original article first appeared on ONFloriculture.com

Print this page